Predictive atau Condition Based Maintenance adalah strategi pemeliharaan proaktif yang memungkinkan Anda memantau kinerja dan kondisi mesin Anda secara real time. Hal ini akan memungkinkan Anda meningkatkan keandalan alat berat dan memprediksi secara akurat kapan peralatan Anda perlu dirawat —daripada menunggu sampai rusak. Menggunakan kombinasi sensor kabel atau nirkabel, Internet of Things (IoT), mekanika tambahan, pembelajaran mesin, dan analisis data, portofolio alat pemeliharaan prediktif Acoem akan membantu bisnis Anda mengantisipasi masalah sebelum terjadi. Jadwalkan aktivitas pemeliharaan pada waktu yang tepat, terima peringatan potensi masalah dengan tingkat kepastian, dan tingkatkan produktivitas industri Anda secara keseluruhan.

Wireless diagnostic solution for critical assets

Real-Time Monitoring of Predictive maintenance powered by artificial intelligence (AI), 8-32 Channel Simultanuous

Early detection of faults on slow rotating shafts with Shock Finder™

Built-in Accurex™ Artificial Intelligence Analysis

Unlocking the business value of Industry 4.0 with edge computing

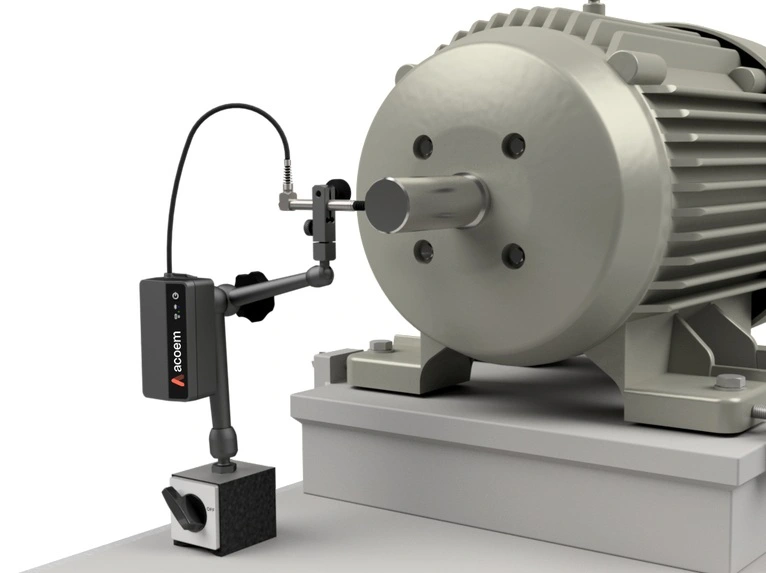

An app-based, entry-level shaft alignment tool

Pre-alignment tool

Bearing Health Checker

Innovative wireless measurement

3200 lines ZYXtrum™ display

Smart 3d indicators

Audio listening

Vibration Analyzer 1-4 Channel

Accurex™ Artificial Intelligence quickly diagnosis of the issue

3-Axis, Wireless Sensor, Built in camera and Stroboscope

Perform in-field balancing operations with easy

Precision Shaft Alignment Made Simple

ACOEM ECO PRO

Smart Balancer 2 or 4 Channel

Graphic display of measurements and weight positions

Trial weight estimation, Simulation Result

Result assessment according to ISO 10816-3 and ISO 1940

Automatic and customizable word report with histograms picture and spectra

Advanced wireless diagnostics for balance-of-plant assets

The smallest wireless triaxial vibration and temperature sensor

24/7 access to actionable data

Accurex SE: AI-powered smart anomaly detection

Achieve precision with the Acoem AT-400 high-end dual-axis shaft alignment system

![]()

![]()

![]()

![]()

![]()

![]()

ACOEM

ACOEM