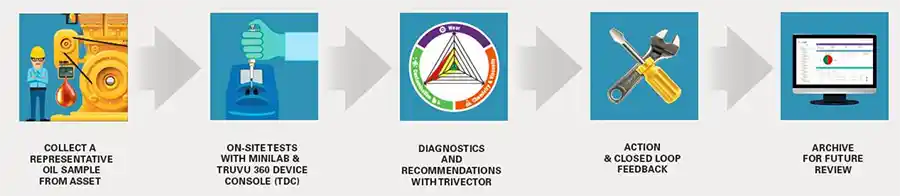

TruVu 360™ Enterprise Fluid Intelligence simplifies and streamlines the on-site oil analysis process, so high-quality information and actionable intelligence leads to effective decision making.

- Closes the gap between recommendations on the oil analysis report, maintenance actions taken and findings for continuous improvement.

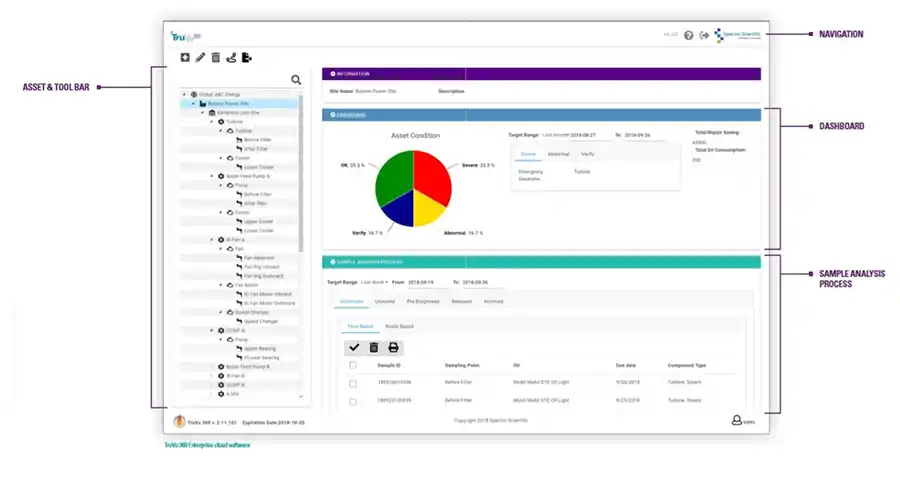

- Offers an intelligence dashboard so management has visibility into the effectiveness of the global program.

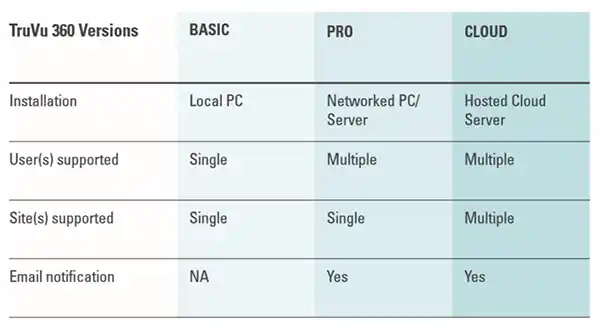

New TruVu 360 Basic and Pro configurations for local installs!

- Highlights

- Resources

- Videos

TruVu 360 Real-time Fluid Intelligence platform delivers real benefits that meet business goals and objectives:

Speed

| Quality

|

Simplicity

| Intelligence

|

The TruVu 360™ platform manages process, information flow and a maintenance dashboard

Achieve More with Global Access to Local Intelligence

TruVu 360 Enterprise Fluid Intelligence addresses the need for standardizing workflows on a global scale and sharing data and intelligence across the enterprise.

- One, standard on-site oil analysis process

- High-quality, actionable information applied locally to improve productivity and reduce costs

- Global intelligence accessible by users and management for continuous improvement

A True View of Process, Information and Intelligence

A Simple Path from Data to Intelligence

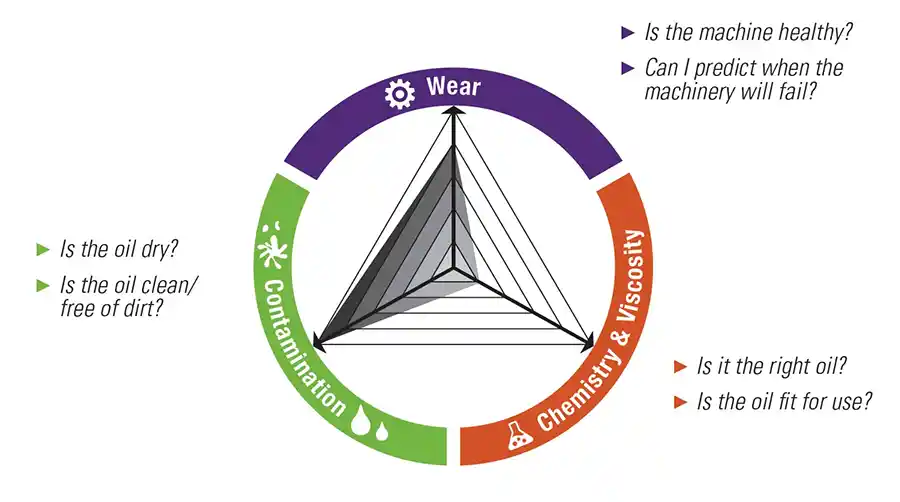

Intuitive TriVector™

Representation of oil analysis diagnostics.

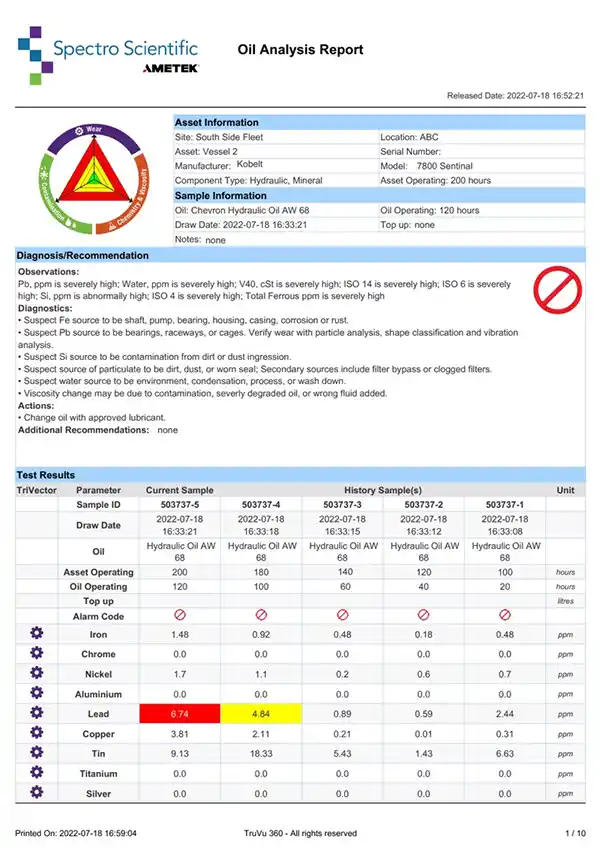

TruVu 360 Report

Includes TriVector chart, historical data color coded for parameters exceeding alarm limits, single parameter trend charts for up to (39) parameters, multi parameter trend graphs by Trivector category, wear images, diagnostics and recommendations.

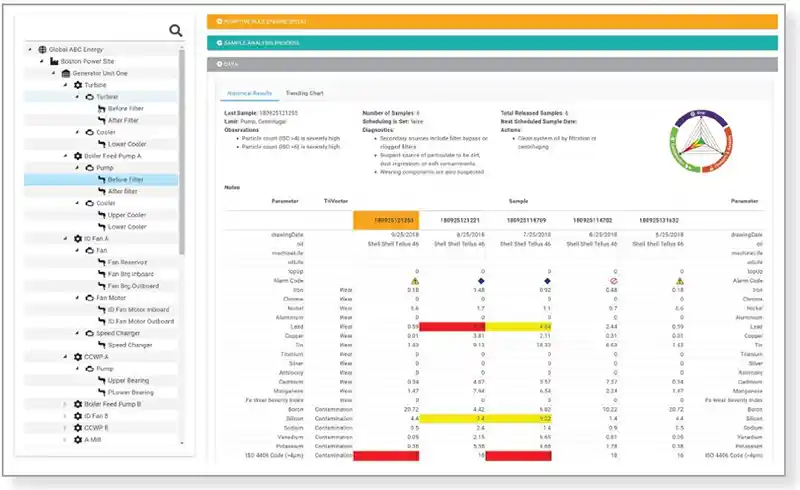

TruVu 360 trending chart and historical sample data

TriVector chart, diagnostics and recommendations for the last sample is also shown. Interactive display of multiple parameters trend.

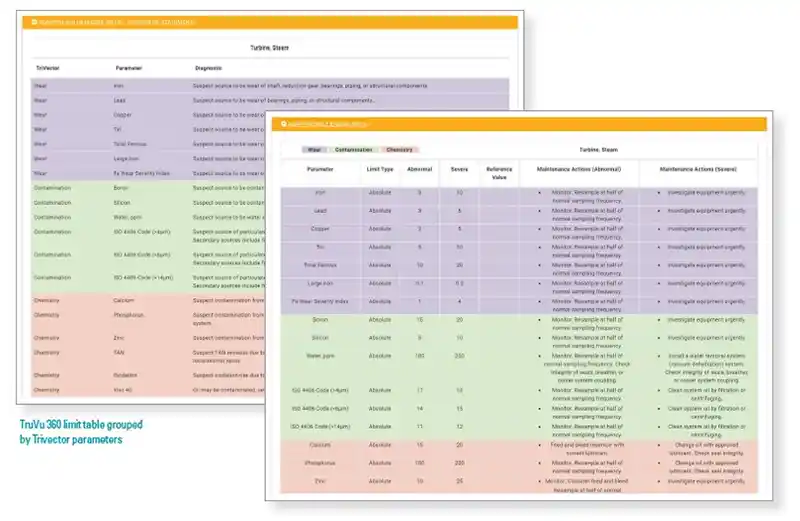

User-configuable Diagnostic Sets

Open architecture Diagnostic Sets allows user to easily customize rules for continuous improvement.

- Factory alarm limit tables for common components, customizable for each asset.

- Software generated alarm codes, diagnostics and recommended actions that can be adapted to user requirements.

Lab Quality On-Site Without a Conventional Lab

TruVu 360 solutions address common hurdles in implementing on-site oil analysis.

| Conventional On-Site Lab | TruVu 360 Solutions |

| High capital investment | TruVu 360 enabled MiniLab costs about 1/3 of a full size laboratory |

| Large space and special facilities needed | Tabletop with no special facility requirements |

| Uses Hazmat chemicals | No hazardous chemicals and reagents, small sample volume, minimum waste stream |

| Lubricant experience required | TriVector report, built-in oil scheduling, easy-to-use testing interface, default component andalarm limit templates, open rule engine for quick startup and continuous improvement |

| Start up time can take months | TruVu 360 based MiniLab start up is less than one week |

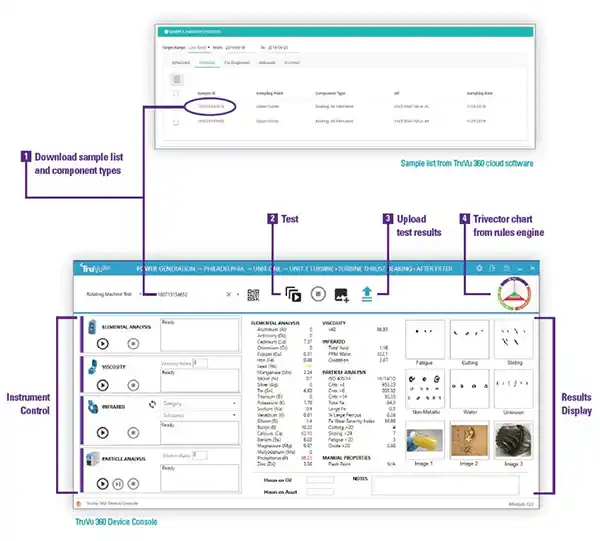

TruVu 360 Device Console Simplifies On-Site Testing

Configurations

Three versions are offered to meet the needs of a company’s size and policies