The latest SpectrOil M series is the eighth generation RDE Optical Emission Spectrometer for elemental analysis in oil and fuel. It is a compact, rugged, transportable and easy to use optical spectrometer that meets military shock and vibration and environmental test standards. The analyzer can be placed in the toughest remote locations around the globe, while still maintaining the laboratory grade accuracy and sensitivity needed for aerospace engine test requirements.

Principle of Operation

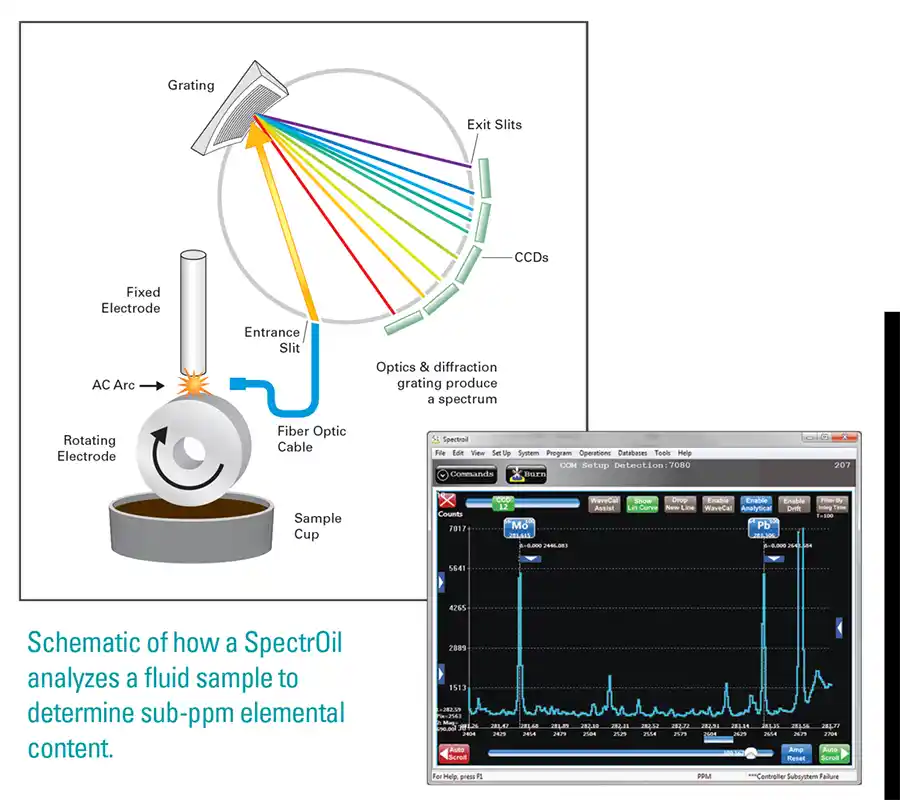

SpectrOil RDE-OES consists of three main components. These components are:

- Excitation Source – introduces energy to the sample. This includes a high voltage AC source that applies voltage across a small gap formed by a purified graphite rod and disc, with the disc rotating and picking up oil from the sample holder under it.

- Optical System – separates and resolves the resulting emission from that excitation into its component wavelengths.

- Readout System – detects and measures the light that has been separated into its component wavelengths by the optical system and presents this information to the operator in a usable fashion.

A specific calibration program is applied to raw spectrum which eliminates the matrix effect, so results are compliant to ASTM standards. Then user only needs to select the calibration profile for specific fluids. So, switching from oil to fuel to coolant or water only takes seconds, not hours like ICP and other instruments.

Key Features

• Rugged frame that meets military shock and vibration and environmental test standards (JOAP CID-0191), designed for remote locations and frequent transportation

• No sample preparation

• 30 second analysis time

• Analyzes up to 31 elements simultaneously

• Self-sustained with built-in industrial touch panel PC

• Simple to operate without special training or background

• No special utilities or gases required, only AC power

ASTM Standards

• Conforms to ASTM D6595 – “Standard Test Method for Determination of Wear Metals and Contaminants in Used Lubricating Oils or Used Hydraulic Fluids by Rotating Disc Electrode Atomic Emission Spectrometry”

• Conforms to ASTM D6728 – “Standard Test Method for Determination of Contaminants in Gas Turbine and Diesel Engine Fuel by Rotating Disc Electrode Atomic Emission Spectrometry

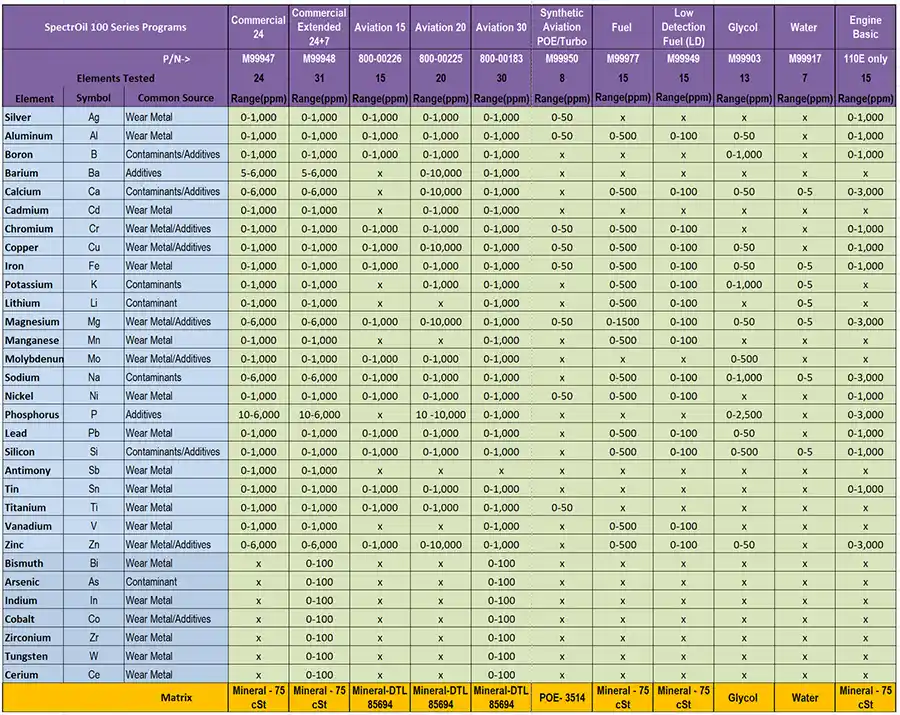

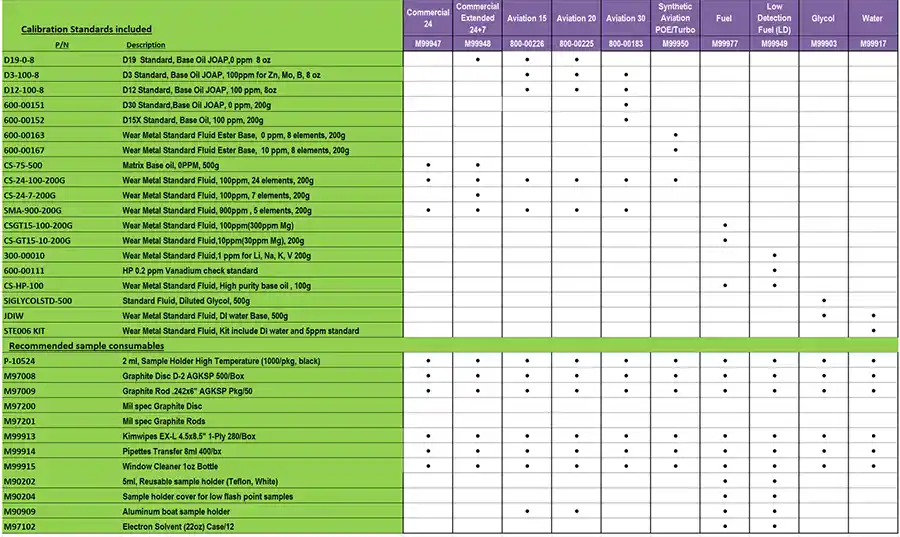

Calibration Programs

Consumables used by calibration programs

To ensure accurate and stable measurement results, different consumables are used for different calibration programs. Only Spectro Scientific certified consumables are qualified to meet performance specifications.

Product Models

The SpectrOil family of elemental analysis spectrometers consists of the SpectrOil M/C-W for commercial oil analysis, the SpectrOil M/N-W for military applications, SpectrOil M/F for Gas Turbine and Diesel engine fuel analysis and the SpectrOil M/F-LD with lower detection limits for alkaline metals and V for GE gas turbines. All versions of the SpectrOil M family are identical in hardware and differ only in their application and the way they are calibrated.

| Model | Calibration Included | Optonal Calibration |

| M/N | M99941 | Any in above table |

| M/C | M99947 | Any in above table |

| M/F | M99977 | Any in above table |

| M/F LD | M99949 | Any in above table |

Fuel Analysis with SpectrOil M/F

Pre-conditioning of the fuel before it reaches the gas turbine is a prerequisite for installations using heavy petroleum fuel. Spectrometric analysis with the SpectrOil M/F-W determines the amount of treatment required and the efficiency of that treatment. In particular, sodium and potassium must be accurately measured to less than one parts per million (ppm), and vanadium concentrations must be determined to calculate the amount of magnesium treatment compounds to be added to the fuel. Analysis requirements start with the delivery of the fuel, continue through fuel handling, and end only as the fuel is injected into the turbine.

MF-LD extends the lower limit of detection even further for alkaline metals such Li, NA, K and V down below 100 parts per billion (ppb) for No.2 Diesel, specifically required by some turbine OEMs to reduce corrosion on turbine blades.