Particle Analyzer

The LaserNet 200 Series allows reliability professionals to quickly and easily assess machinery health in just minutes. By testing only a few milliliters of fluid, users see a complete picture of machine wear and particulate contamination. This enables the user to determine filtration efficiency, the type of wear mode occurring, and the change in ferrous debris concentration, for maintenance action.

With a simple push of a button, a comprehensive picture of machine wear is generated with only a few parameters:

- Particle cleanliness codes, such as ISO 4406 and ASTM D6786, indicate the overall cleanliness of the oil

- Ferrous Wear Severity Index (FWSI) indicates overall severity of the machine wear condition

- Count of large cutting, sliding and fatigue wear, along with non-metallic particles, indicates the source of the particles

Having this information allows reliability professionals to make informed decisions on the maintenance of their critical assets.

Key Features

Complies with ASTM D7596 – Standard Test Method for Automatic Particle Counting and Particle Shape Classification of Oils Using a Direct Imaging Integrated Tester

Particle count features

- Particle count, size distribution and codes (ISO 4406, NAS 1638, NAVAIR 01-1A-17, SAE AS 4059, GOST, ASTM D6786, HAL, and User defined bins.)

- Particle Count for all particles from 4 μm to 100 μm

- Highest saturation limit, up to 10,000,000 particles/ml with a coincidence error <2%

- Designed for mineral oils, synthetic oils, hydraulic fluids, turbine and distillate fuels

- Viscosity range ISO15 to ISO320, undiluted

- Images through dark fluids containing up to 1% soot content with automatic laser gain control

- Greater than 20 microns error corrections for water and air bubbles

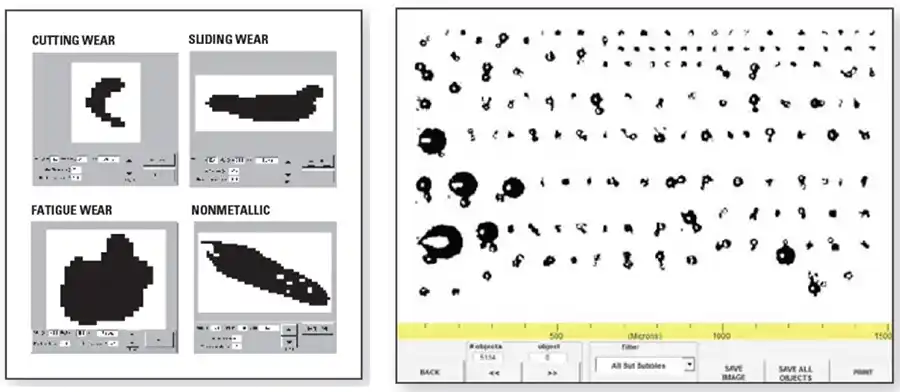

Automatic shape classification features

- Automatically classify particles larger than 20 micron (maximum diameter)

- 7 classes – cutting wear, sliding wear, fatigue wear, non-metallic, water droplets, air bubbles, fiber. User can reclassify particles manually

- Numerical count of each classes can be used for trending analysis

Ferrous content and particle analysis features

- Total ferrous concentration per ASTM D8120

- Reports large Ferrous concentration (PPM), percentage of large Ferrous particles (PLFP), Ferrous Wear Severity Index (FWSI)

- 20 second additional test time for Ferrous measurement

- Ferrous measurement performed in concert with particle count and automated shape classification (<4 microns per sample)

- Detects ferrous particles over 25 microns, equivalent circular diameter

Optional Auto-Samper for high throughput sample processing

All LaserNet 200 series systems are designed to work with an optional auto-sampling processor (ASP).

- It holds 24 samples in a carousel sample tray

- Automatically stirs sample bottles to homogenize particle distribution before each measurement

- Automatically cleans and rinses between measurements to eliminate cross contamination

- Unattended operation up to 250 samples per day during typical lab operations. Throughput varies by oil viscosity and cleanliness target expectation

Analytical Tests and Features by model:

There are four models in the LaserNet 200 series. The table below details the difference among the four models.

| LaserNet 200 Comparison | 210 | 215 | 220 | 230 |

| Total particle count & codes | v | v | v | v |

| Non-metallic particles (sand/dirt) | v | v | v | v |

| Free water measurement | v | v | v | v |

| Air bubble/water droplet correction | v | v | v | v |

| Wear particle classification | v | v | ||

| Total Ferrous concentration | v | v | ||

| Ferrousparticle count & size distribution | v | v | ||

| Large ferrous concentration | v | v | ||

| Autosampler option | v | v | v | v |

Operating principles

The LaserNet 200 Series system employs an innovative, patented approach to testing the fluid directly from the sample bottle. The core of the device combines a direct imaging particle analyzer with a sensitive magnetometer together to generate both particle counts, images and ferrous concentration in ppm. Oil and fluid samples are passed through a flow cell, illuminated by a laser, and a CCD video camera counts and classifies the particles from the image data. This technique provides the user with a very reliable and accurate particle counter that can tolerate a wide range of dirty and clean samples, with varying viscosities.

The capability of the LaserNet Fines to capture the actual wear particle silhouette allows for an ‘Automated Ferrography’ capability for wear particle classification. All particles larger than 20 μ are classified by a neural network in categories such as cutting, fatigue, severe sliding, non-metallic, free water and fibers.

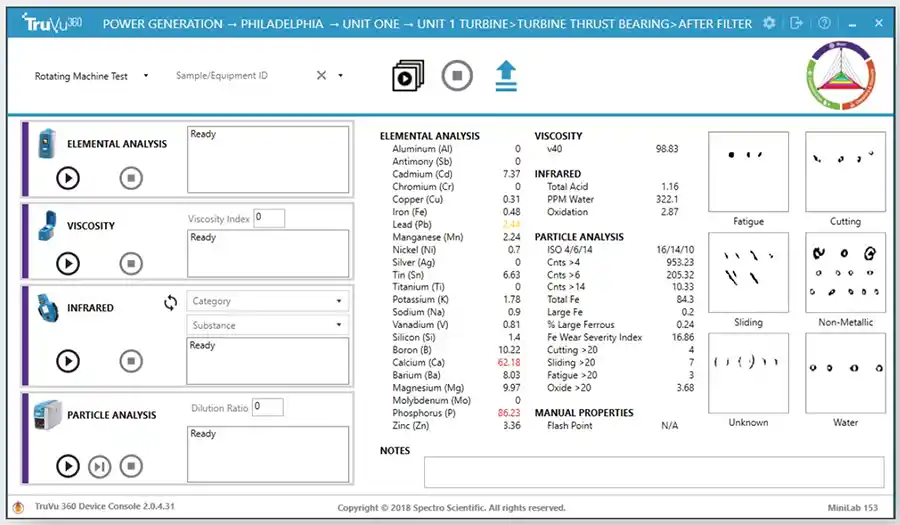

Data Management

The LaserNet 200 Series has a data export capability to laboratory LIMS systems as well as comma or tab delimited text file formats. The wear images can be exported as .jpeg or .bmp files.

Spectro Scientific’s TruVu 360 Device Console (TDC) fully integrates the LaserNet 200 with the TruVu 360 Enterprise Fluid Intelligence platform.

The LaserNet Series system fulfills the wear and contamination measurement of the MiniLab system, and it is designed to communicate seamlessly with the TruVu360 fluid intelligence platform.