The FluidScan® 1000 series handheld Infrared oil analyzer provides a direct quantitative measurement of a lubricant’s condition. It plays an important role in Machine Condition Monitoring (MCM) for proactive and predictive maintenance in Reliability Management programs. Using the device, you can determine when oil needs to be serviced due to degradation of the oil chemistry or contamination by other fluids such as water or the wrong oil. The FluidScan is compliant with ASTM D7889 “Standard Test Method for Field Determination of In-Service Fluid Properties Using IR Spectroscopy”.

Dedicated Direct Infrared Spectrometer for Lubricant Condition Monitoring

- Designed for field use applications with no moving parts

- Compact for hand-held, portable usage

- Actionable results for immediate decisions

- Water, TAN, and oxidation for lubricants used in gearboxes, turbines, and hydraulic systems

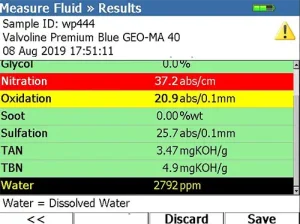

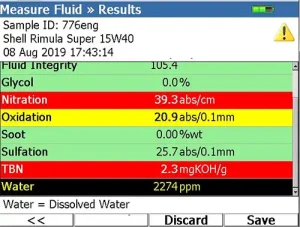

- TBN, water, glycol, soot, additive depletion, and oxidation/sulfation/nitration for engine oils

- Other applications include transmissions, greases, lubricant/biodiesel/fuel blending or QC.

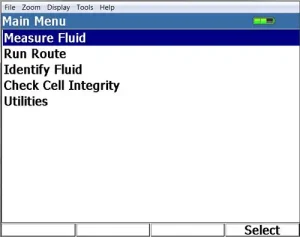

Easy to Use

- Needs just one drop of oil and one minute to test

- No solvents required to clean

- Easy to interpret color-coded, user adjustable alarm limits

Determine when in service oil not fit for use

- Direct immediate measurement of water, TAN and oxidation for lubricants used in gearboxes, turbines and hydraulic systems

- Also measures TBN, water, glycol, soot, additive depletion and oxidation for engine oil

Highly Repeatable and Reproducible Results

- ASTM D7889 Compliant – “Standard Test Method for Field Determination of In-service Fluid Properties Using IR Spectroscopy”

- Excellent correlation to KF water, TAN and TBN laboratory tests

- Reproducibility and repeatability comparable to benchtop FTIR method ASTM E2412

- Data analysis compliant to ASTM E1655

- It also fulfils the National Emission Standards for Hazardous Air Pollutants for Reciprocating Internal Combustion Engines (NESHAP RICE) requirements for extending oil change intervals in engines and back-up generators when used in conjunction with the Spectro MiniVisc 3050 Portable Viscometer.

Comprehensive Fluid Library and Application Categories

- Over 850 fluids for immediate operation

- Different fluid libraries available based on application

- Fluid libraries can be customized by the user in the field

Measured Parameters

One of the advantages of the FluidScan over laboratory FTIR is its ability to report absolute quantitative results for critical properties such as TAN and water contaminations for industrial lubricants or TBN, water, glycol, and soot for engine oils. The below table specifies different parameters provided by FluidScan depending on the oil type.

| Application Categories | Properties Measured by FluidScan |

| Transmission | Water (PPM), Oxidation (Abs/0.1mm), Fluid Integrity (unitless) |

| Hydraulic – Fire resistant (Phosphate Ester) | Water (PPM), TAN (mg KOH/g) |

| Hydraulic – Aerospace (Synthetic Hydraulic Fluid) | Water (PPM), Oxidation (Abs/0.1 mm), Alien Fluid mineral based (MIL-H-2304) (%), and Alien Fluid engine oil (ML-H-23699) (%) |

| Heat Transfer (Quenching Oil) | Water (PPM), Oxidation (Abs/0.1 mm) |

| Industrial (Steam and CCGT Turbine, Hydraulic, Compressor, Chiller, Gear, etc.) | Water (PPM), Oxidation (Abs/0.1 mm), TAN (mg KOH/g) |

| Turbine Aerospace (Synthetic Gas Turbine Oil) | Water (PPM), TAN (mg KOH/g), Antioxidant (% depletion) |

| Engines (Engine oil for different engine types, including Gasoline, Diesel, Heavy Duty Diesel, HFO, Natural Gas, etc.) | Water (PPM), Oxidation (Abs/0.1 mm), TBN (mg KOH/g), TAN (mg KOH/g) (Natural Gas only), Sulfation (Abs/0.1 mm), Nitration (Abs/cm), Soot (%), Glycol (%), Anti Wear (%)Biodiesel Dilution (%) (Diesel & Heavy Duty Diesel – Engine Oils) |

| Ethanol in Gasoline | Ethanol (%) |

| FAME in Diesel | FAME (%) |

| Biodiesel Feedstock | Water (PPM), FFA (%) |

| Biodiesel | Water (PPM), TAN (mg KOH/g), Total Glycerin (%) |

| Grease | Water(abs/0.1mm), Oxidation (abs/0.1 mm), Water Index (unitless) |

Fluid Manager desktop application provides:

- Report capability

- Device synchronization

- Data backup

- Asset Manager database

Applications include:

- Mineral and synthetic oils used in gear boxes, engines, transmissions

- Hydraulic systems, turbines and other machinery components

- Biodiesel/Fuel

- Quality assurance of new oils

Innovative water and fluid indentity methods

- Patented total water algorithm for both dissolved and free water

- Solvent free alternative to Karl Fischer titration

- Water index for grease condition monitoring

- Fluid integrity to determine fluid mix ups

Operating Principle

Innovation in hardware

At the core of the FluidScan is a patented, mid-infrared spectrometer. The centerpiece is a grating dispersive optical system, with a solid state wave guide to reduce the light leakage and improve signal-to-noise ratio. This design approach eliminates moving parts from the system with inherent durability and also eliminates any frequent recalibration needs for field use.

Methods Unique to FluidScan

- Patented Total Water measurement for industrial fluids (both dissolved and free water)

- Fluid integrity parameter for oil condition trending and to help detect mix-ups

- Water Index for grease condition trending

Multivariate Calibration and Fluid Classification

Generic calibrations for parameters like TAN, TBN, and water do not provide credible results across all oil types. To overcome this, the FluidScan uses sophisticated chemometric techniques like those described in ASTM E1655.

- Multivariate calibrations can account for interferences such as the effects of water on the infrared signatures related to TAN in gas turbine oils, as described in ASTM E2412.

- A classifier is also used to assign the oils in the fluid library, based on their chemistry, into different families that share an algorithm set. Using this classification method, users in the field can quickly match a new oil to the fluid library for reliable results.

FluidScanParameter | Method | Correlates To |

AW Additive | Complies with ASTMD7889 | ASTM D7412/E2412 (FTIR) |

Oxidation | Complies with ASTMD7889 | ASTM D7414/E2412 (FTIR) |

Sulfation | Complies with ASTMD7889 | ASTM D7415/E2412 (FTIR) |

Nitration | Complies with ASTMD7889 | ASTM D7624/E2412 (FTIR) |

Glycol | Uses techniques describedin ASTM E1655 | ASTM E2412 (FTIR) |

Soot | Complies with ASTMD7889 | ASTM D5967 (Thermo-Gravimetric Analysis) |

TBN | Uses techniques describedin ASTM E1655 | ASTM D4739 (Potentiometric Titration) |

TAN | Uses techniques describedin ASTM E1655 | ASTM D664 (Potentiometric Titration) |

Water | Uses techniques describedin ASTM E1655 | ASTM E2412 (FTIR)/ASTM D6304 (KarlFischer Titration) |

Product Models

| PN | FluidScan 1000 | FluidScan 1100 |

| Default library | One free library from FL364 to FL371 at time of purchase | Industrial |

| Upgradable to full library | Yes | Yes |

| Total water license | Optional | Optional |

| Route base analysis | No | Yes |

| OilView Interface | No | Yes |

| TruVu 360 Device Console Interface | No | Yes |

| Intended application | Portable Analysis | On-Site Analysis |