Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

The FerroCheck 2000 Series of portable ferrous analyzers offer accuracy and convenience for total ferrous measurement of in-service lubricating oil and grease. Fast and easy to use samples are analyzed in less than 30 seconds. Small sample volumes of just 1.5 ml of oil or 0.75 ml of grease are needed to measure ferrous content in part per million (ppm) by weight. The FerroCheck measures the total ferrous content of both small particles from normal machine wear and large abnormal wear particles.

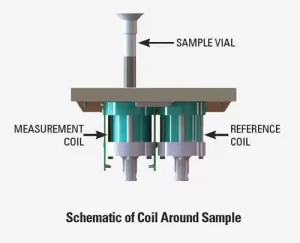

The core of the FerroCheck 2000 is a pair of precision rounded coils that when powered, generate magnetic fields. When a small amount of in-service oil is inserted into one of the coils, ferrous particles, such as Iron, Nickel, and Cobalt, interact with the magnetic field and introduce current changes in the coils. The amount of current change is proportional to the amount of Ferrous particles in the oil, calibrated by weight in parts per million (ppm).

Key Features

Measure total ferrous content in part per million by weight

- Measures all ferrous material-normal machine wear and large abnormal wear particles.

Accurate and repeatable

- Low limit of detection.

- Highly repeatable – 3% of reading

- Wide range of measurement

- Validation standard included

Easy to use

Measuring Oil

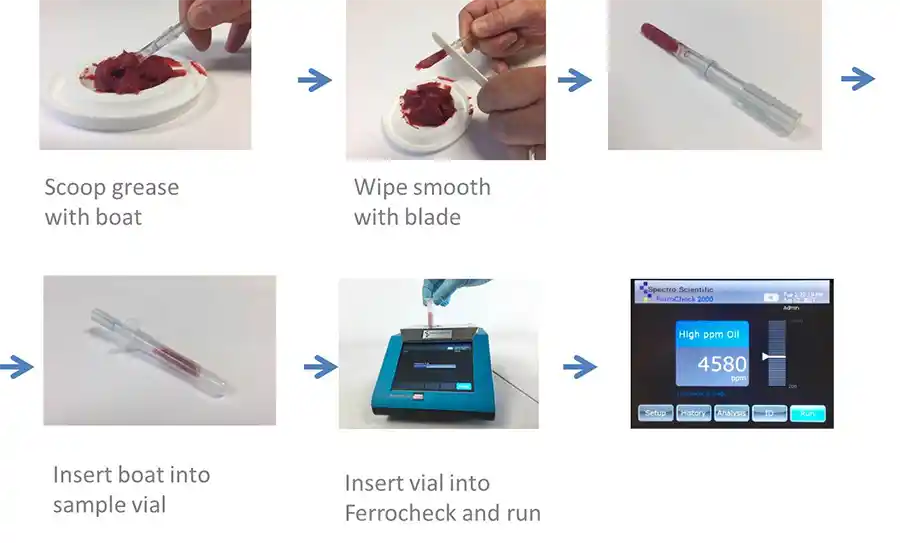

Measuring Grease

- Solvent- free operation and no sample preparation

- Requires less than 2 ml of sample to test

- Results in 30 seconds

Portable, battery powered design

- Lightweight and fits easily into a toolbox or carrying bag and capable of operation for over 4 hours before recharge. Plug unit in for continuous use.

Expanded I/O capability

- Automated data storage, export files in csv format or use AMS Oilview software interface

ASTM Compliance

- ASTM method D8120 “Standard Test Method for Ferrous Debris Quantification”

Field or Laboratory use

- Accurate, repeatable and stable results over a wide temperature range, designed for both laboratory and field usage

- Rechargeable battery

Product Information

| PN | Ferrocheck 2000 | Ferrocheck 2100 |

| Applications | Lubricant oil | Lubricant oil and grease |

| Output | Total Ferrous, parts per million by weight | |

| Methodology | ASTM D8120 | |

| Standard Calibrated Ranges | 0-2,000 ppm, 2,000-10,000 ppm | 0-2,000 ppm and 2,000-10,000 ppm for oil 0-2000 ppm, 2000 ppm-15% for grease |

| Test Time | < 30 s | |

| Limit Of Detection | 3 ppm | |

| Repeatability | 3% RSD | |

| Calibration | Ferrous standards provided | |

Instruments

Part numbers | Instruments |

| 800-00071 | FerroCheck 2000 Ferrous Monitor for oil |

| 800-00069 | FerroCheck 2000 standard accessories kit. Includes instrument carrying case, dust cover,1000 sample vials, 200 vial stoppers, and oil validation standards. |

| 800-00081 | FerroCheck 2100 Ferrous Monitor for oil and grease |

| 800-00082 | FerroCheck 2100 standard accessories kit. Includes instrument carrying case, dust cover, 1000 sample vials, 300 grease boats and blades, 200 vial stoppers,and oil and grease validation standards. |

Consumables

Part numbers | Description |

| 800-00070 | FerroCheck 2000 consumables kit (500 Samples). Includes 500 sample vials,100 vial stoppers, and validation standards. |

| 800-00075 | FerroCheck 2100 consumables kit (500 Samples). Includes 500 sample vials,100 vial stoppers,150 grease boats and blades, and validation standards. |

| 600-00033 | FerroCheck sample vials, qty 100 |

| 600-00031 | Grease sample boats and blades, qty 50 each |

| 600-00032 | Grease boat, blade and vial kit, qty of 50 each |

| 600-00074 | FerroCheck sample vial stoppers, qty 100 each |

| 600-00113 | 100 ppm verification fluid for FerroCheck (oil) |

| 600-00114 | 5000 ppm verification fluid for FerroCheck (oil) |

| 600-00124 | Verification standard for grease, high range |

| 600-00125 | Verification standard for grease, low range |

Combination Kits

FerroCheck 2000 is a great companion device when coupled with other portable oil analysis tools for different applications. Here are a few examples:

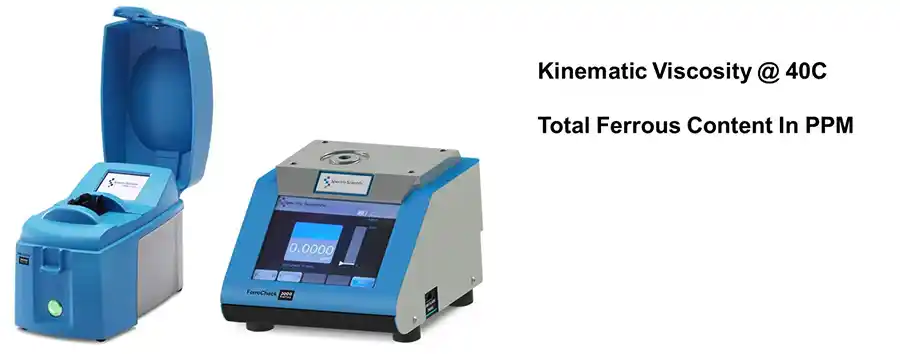

Basic Oil Analysis Kit:A quick check with viscosity and ferrous particle concentration in the field is the simplest way to make sure oil is good and machine wear is within alarm limits. The FerroCheck 2000 Series total ferrous particle measurement and the MiniVisc 3050 viscometer combination provides basic oil analysis for field service professionals.

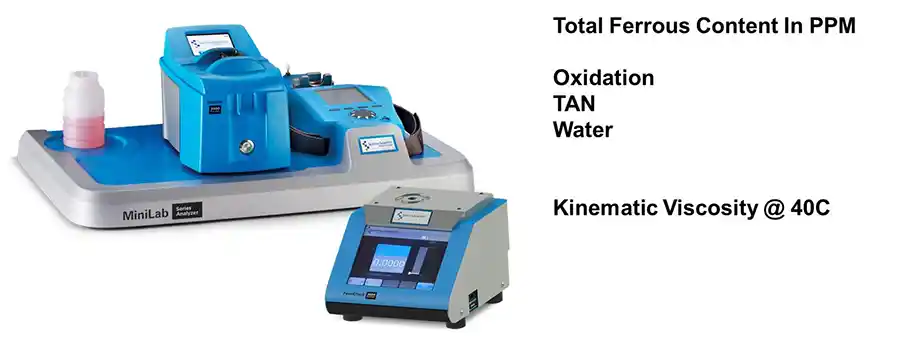

MiniLab 33 (FluidScan, Viscometer and FerroCheck Combo):Trivector™ MiniLab configuration that tests oil condition (Oxidation, TAN) with the Fluidscan InfraRed Spectrometer, Kinematic viscosity @ 40C, liquid contamination (water) and ferrous content for abnormal wear. It is ideal for small- to medium-sized industrial or power plants looking to start an on-site oil analysis program.