Commercial field service professionals managing fleets of high-value assets require portable, lightweight devices that provide rapid oil analysis results with quality similar to oil analysis labs. Funded by the United States Department of Defense (DoD), then developed and commercialized by Spectro Scientific, the FieldLab C Series is state of the art military technology now available for commercial use.

The FieldLab C Series integrated system requires only a few milliliters of oil to complete four comprehensive tests to help maintain readiness of critical assets while economically managing maintenance costs.

Easy to Use

- No solvents or reagents and small sample volumes required

- Intuitive Interface and simple workflow minimizes human error

- Built-In Video Instruction for inexperienced users

Key Features

- Rugged design with battery power for on-site field use

- No solvents or chemicals required

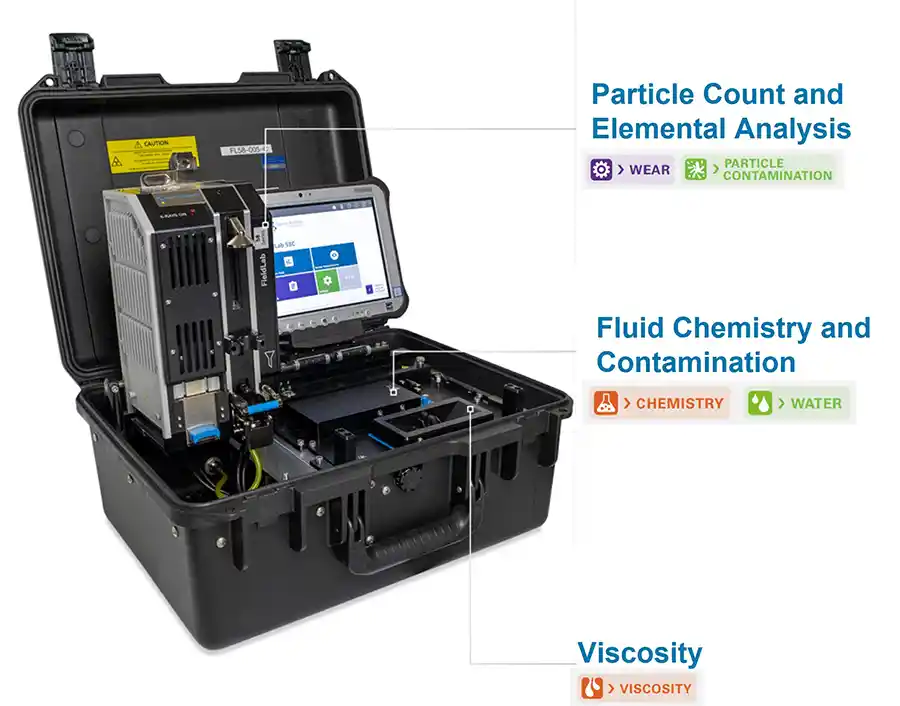

- Complete oil analysis lab with 4 technologies integrated into a small case

– X-Ray Florescence (XRF) spectrometer for elemental analysis

– Filter Particle Quantifier (FPQ) pore blockage particle counter

– Infrared (IR) spectrometer

– Kinematic viscometer (40°C) - 4 tests generate more than 20 oil analysis parameters in less than 10 minutes

- Built-in controller for measurement, data, and asset with touch screen interface

- Uses only 12 mL of oil

- ASTM compliant

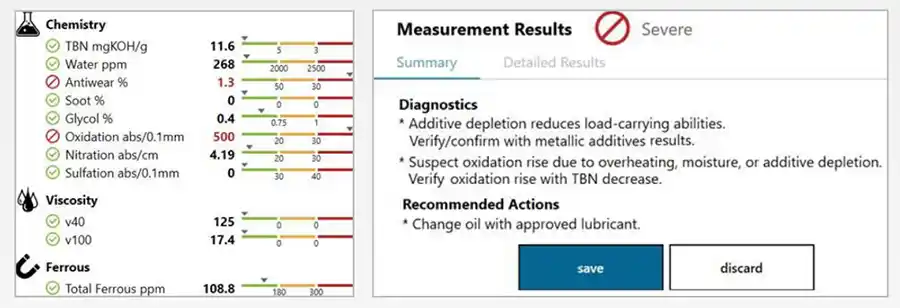

Smart Diagnostics, Flexible Alarm Setting

- Easy to read oil analysis report with clear Observations, Diagnostics, and Recommended Actions.

- Factory alarm limit tables for common components

- User-customizable alarm limits and diagnostic sets for continuous improvement over time

Optional Interface with TruVu 360 Fluid Intelligence Software

- Summary dashboards for visibility into asset condition and fleet readiness

- Management dashboard for CBM oil-analysis program management views of cost savings and program key performance indicators (KPIs)

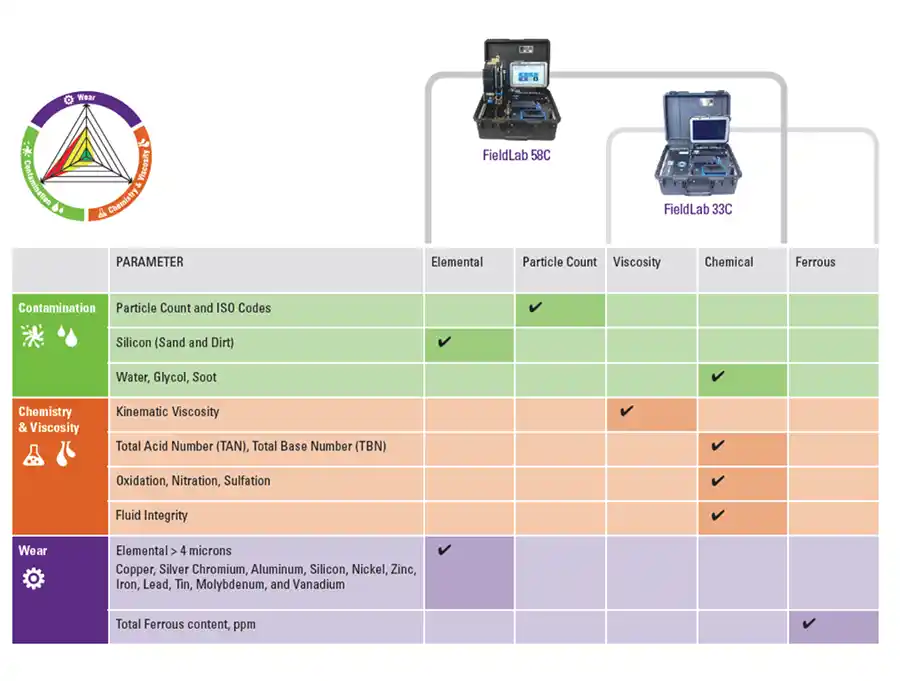

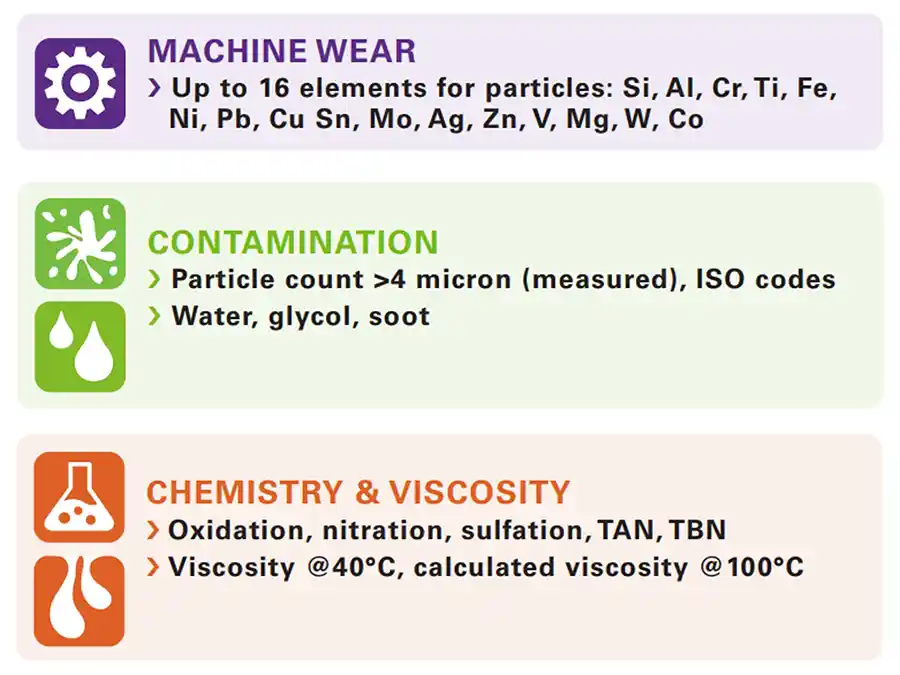

Key Parameters

Principles Of Operation

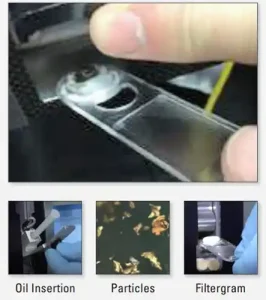

Particle Count and Elemental Analysis — ASTM D812 ![]()

Particle counts are generated using our patented FPQ pore blockage particle counter (ISO 21018-3). It captures the particles of interest for severe wear detection onto a unique filtergram. This debris may now be measured on the companion XRF spectrometer for immediate results in ppm for up to 16 elements.

Wear and contamination particles larger than 4 microns deposit on the filtergram, and are tested using an X-Ray Florescence (XRF) spectrometer. The concentration (in ppm) for up to sixteen different elements is reported.

The filtergram coupon can be stored for future analysis, such as microscopic wear debris analysis of particle colors and shapes.

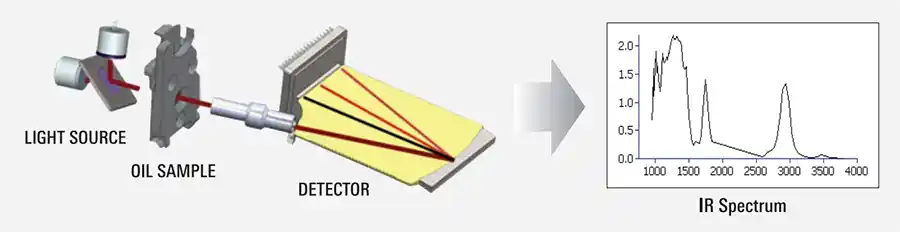

Fluid Chemistry and Contamination — ASTM D7889 ![]()

The IR spectrometer measures the chemistry of the lubricant and contamination in one minute using only one drop of oil; no chemicals or solvents are required. It combines ease of use, ruggedness and laboratory precision in a small package, which is ideal for field use.

The oil condition parameters measured by FluidScan include oxidation, nitration, sulfation, anti-wear additive, Total Base Number (TBN), glycol, soot, and water for engine oil; and oxidation, Total Acid Number (TAN), and water for rotating machine lubricants such as gear oil, transmission oil and hydraulic oil.

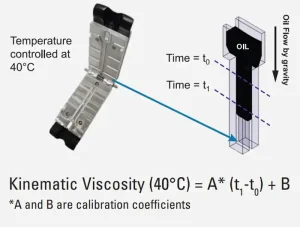

Viscosity — ASTM D8092

Viscosity is measured using a temperature-controlled kinematic viscometer with a patented split-cell design.

A funnel, with a 100 micron gap, is formed in the center of the cell. Optical sensors in the cell detect the flow of oil under the influence of gravity. The time it takes the oil to flow through the cell is proportional to the viscosity of the oil. When open, the cells can be cleaned using a non-abrasive wipe. No solvents are required.

FieldLab C Series Models